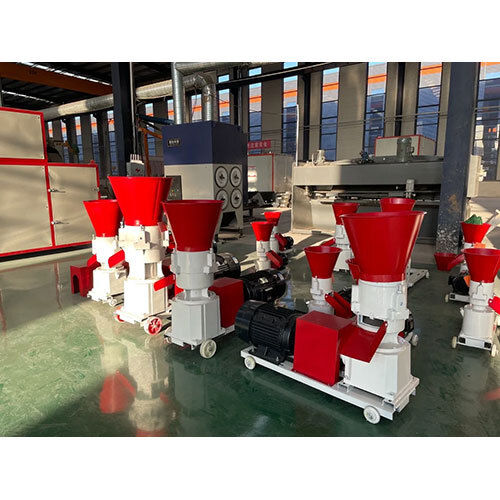

Biomass Pellets Machine

158000 INR/Piece

Product Details:

- Product Type Biomass Pellets Machine

- Power Source Electricity

- Dimension (L*W*H) 84*46*90 Cm Centimeter (cm)

- Weight (kg) 206 Kg Kilograms (kg)

- Production Capacity 50-60 Kg/hr

- Usage & Applications Industrial

- Click to View more

X

Biomass Pellets Machine Price And Quantity

- 158000 INR/Piece

- 1 Piece

Biomass Pellets Machine Product Specifications

- Biomass Pellets Machine

- 50-60 Kg/hr

- 206 Kg Kilograms (kg)

- Industrial

- Electricity

- 84*46*90 Cm Centimeter (cm)

Biomass Pellets Machine Trade Information

- 20 Piece Per Month

- 10 Days

Product Description

A state-of-the-art method for turning a variety of organic resources into high-density fuel pellets is the Biomass Pellet Machine. This machine can handle a wide variety of feedstocks, such as wood chips, sawdust, straw, rice husks, bamboo, palm kernel shells, and other agricultural residues. It is appropriate for both industrial and small-scale use.

Important characteristics:

Invest in sustainable energy with the help of the Biomass Pellet Machine, your eco-friendly, productive fuel production companion!

Important characteristics:

- High Efficiency: This machine guarantees maximum throughput and ideal pellet density thanks to its strong motor and cutting-edge compression technology.

- Sturdy Construction: Constructed from premium stainless steel and alloy parts, it is intended for continuous use in harsh settings.

- User-Friendly Operation: Regardless of the operator's skill level, the simple controls and intuitive UI make it easy to use.

- Versatility: With the ability to produce pellets in varying sizes, it may be used for a range of purposes, such as animal bedding, power generation, and heating.

- Eco-Friendly: It lessens its negative effects on the environment and promotes sustainable energy practices by turning waste materials into renewable energy.

- Safety Features: It guarantees safe operation at all times with its automatic shutdown, overheat prevention, and safety guards.

Invest in sustainable energy with the help of the Biomass Pellet Machine, your eco-friendly, productive fuel production companion!

| Automation Grade | Automatic |

| Briquette Size | 6/8/10 mm |

| Power Required | 7.5 Kw |

| Frequency | 50 hz |

| Capacity. | 50-60 Kg/hr. |

| Dimension | 84*46*90 Cm |

| Weight | 206 Kg |

| Voltage | 415 V, Three Phase |

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese